All four of these saws have the rounded (but not round) boss of fairly early Kenyon backsaws. I suppose the smallest one could be called a sash saw, but, at 14” long, it also does qualify as a tenon saw. The other three are simply really large tenon saws. It’s hard to date them, but I’ll speculate their origin at around 1800 to 1810. Any corrections to that speculation will be welcomed.

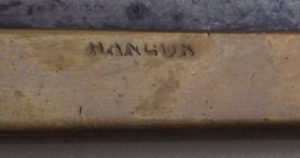

The bottom 14” iron backed saw (the handle of which I’ll fix someday…Ah, someday) is stamped “Kenyon”. The spine tapers from just over 7/8” at the heel to ¾” at the toe, and is 5/16” wide. The handle has a flat chamfer and lacks the little birds mouth at the chamfer end that the top two brass backed saws have (just as the brass backed Seaton Chest saws have). The blade is canted from 1 15/16” at the heel to 1 3/8” at the toe. Screws are 7/16” diameter and the handle is 7/8” thick.

The next saw up has a 17 3/16” blade and the same “Kenyon” stamp. It weighs 2 lbs. There is no taper to the 15/16” deep iron spine, which is also 5/16” wide. Again, a flat chamfer and no birds mouth on this iron backed saw. For some reason a previous owner had added a third screw hole in between the original two and had changed the split nuts out for domed steel screws. I think I’ll eventually change it back to two split nuts. The blade is canted from 3 ½” at the handle to 3” at the toe. With its accretions the blade measures from .030” to .033” thick. The handle is 15/16” thick with 9/16” screws.

Third is the lesser brass back (it’s really too large to call “smaller”), with an 18 1/8” blade and stamped “Kenyon / Cast.Steel”. (Jane Rees has said that we have no tools marked Cast Steel before about 1800, although cast steel was first produced c1740) It weighs 2 lbs. 1 oz. The spine, 15/16” deep at the handle, tapers less than a 32nd of an inch to the toe. It is 11/32” thick and, very unusually, is beveled at both sides of the top rather than rounded as the others are. The blade is canted from 3 5/16’ at the handle to 2 9/16” at the toe. With its accretions it measures from .030” to .033”. The handle is 15/16’ thick with 9/16” diameter screws, and being a brass backed saw it has the little birds mouth at the chamfer stop.

The top saw, with a 19 13/16” blade, is also stamped “Kenyon / Cast.Steel” but in this case the word “Kenyon” is 13/16” long. On the other three saws the “Kenyon” stamp was just under 5/8” long, so here a bigger saw deservedly gets a bigger name. It’s also heavier, weighing 2 lbs. 6 oz. The brass spine is 15/16” deep at the handle and also tapers less than a 32nd of an inch to the toe. It is 5/16” wide. The deep, clean blade is canted from 4 3/16” at the handle to 3 3/8” at the toe and is about .030” in thickness. The handle is 15/16” thick with 9/16” diameter screws. And, unusually among these four saws, the tooth line is slightly breasted. In ink, under the flat bottom horn, is written 11/6 which may be what it originally cost. On page 9 of BSSM is a chart of prices showing that in 1820 Beardshaw would sell a cast steel tenon saw for 8/8. Since this is a brass back of large size, then 11/6 does sound like a reasonable sale price for this saw, an ocean away from it’s place of manufacture.

It’s not obvious from its fine condition, but this saw is over two centuries old. It’s clean and very lightly used, with original finish on the handle and an even patina on the brass. The only change from the original condition is that a previous owner whittled away the underside of the top horn to better accommodate the web of his thumb. There is some staining of the blade (very similar to that on the Seaton Chest sash saw).

It came from upstate NY, near Schenectady, and the seller mentioned that the saw possibly had some connection to the Shakers at nearby Watervliet. I’m a little doubtful of that since it’s hard for me to imagine Shaker craftsmen acquiring such a fine saw and not using the heck out of it over the century or so between when it was made circa 1800 and the fading away of the Shaker communities at the end of the 19c. In any case, whoever owned it certainly took good care of it and put it away carefully.

Chris Schwartz has blogged about his delight at his discovery of just how easy it is to saw well with behemoths like these. He found that, rather than being hard to handle, the weight of these guys keeps them easily on track. All you have to do is push.